Advantages of Spray Foam

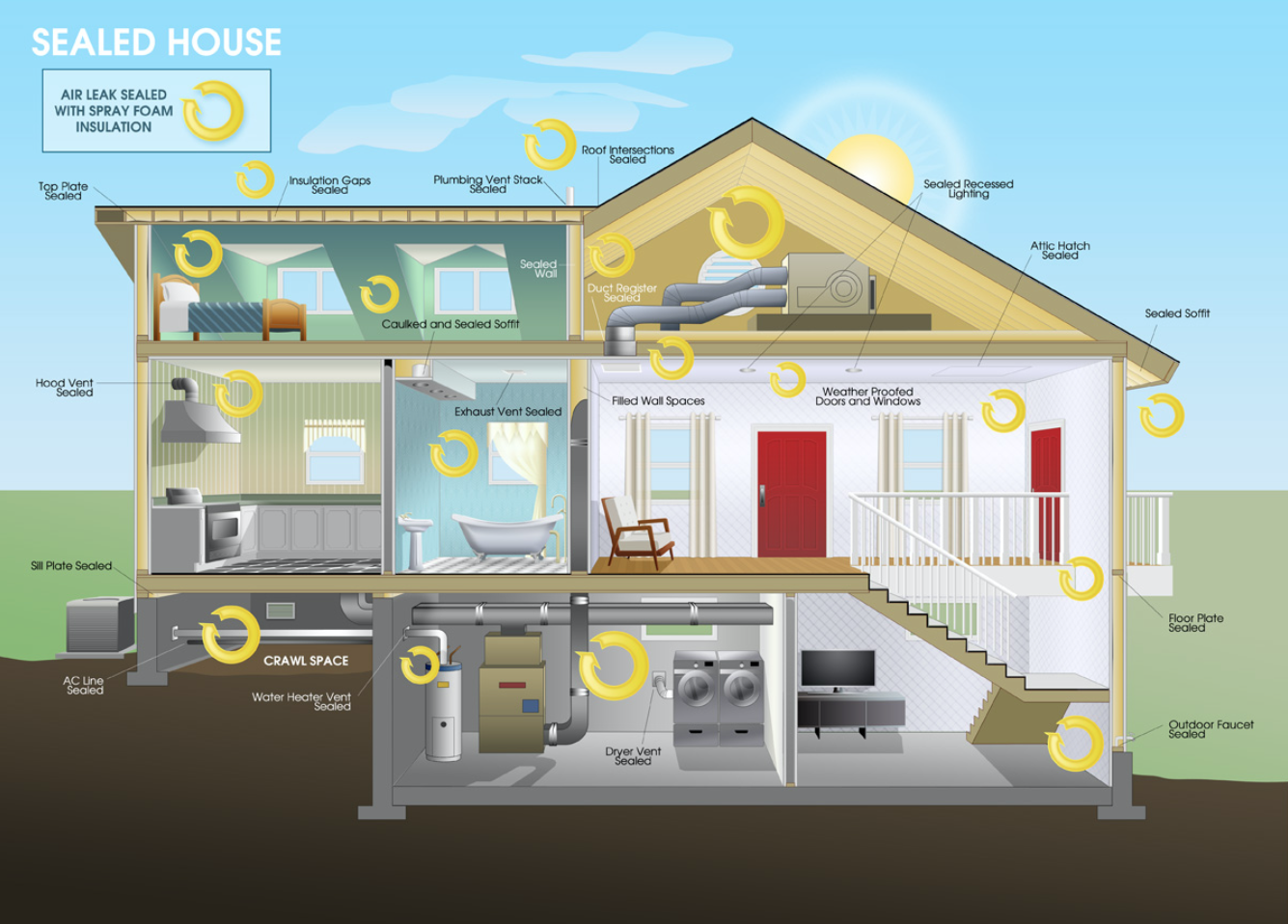

Spray foam is a unique insulation and sealing product. The product is applied on site so it conforms to the surface where it is applied. This application process creates a tight building envelope, which improves energy efficiency.

Spray foam insulation and insulating foam sealants are made by mixing and reacting unique liquid components. The liquids react very quickly when mixed and applied on site, expanding on contact to create foam that insulates, seals gaps, and can form air, moisture, and vapor barriers. Spray foam is versatile and can seal wall cavities, exterior walls, crawlspaces, attics, and small gaps and cracks throughout a house. Spray foam products can limit air infiltration and air movement throughout the home, which helps reduce energy usage, limits intrusion of pollutants and allergens, and makes the home more comfortable.

Each spray foam type and method of application offers unique benefits. There are three primary types of spray foam that can be used for insulation and other specific purposes:

High-Density

3 lbs./cubic ft., closed-cell foam

R-Values start at 5.5 per inch*

Often used for exterior and roofing applications

Medium-Density

2 lbs./cubic ft., closed-cell foam

R-Values start at 5.7 per inch*

Often used for continuous insulation, interior wall cavity fill, and unvented attic applications

Low-Density

0.5 lbs./cubic ft., open-cell foam

R-Values start at 3.6 per inch*

Often used for interior wall cavity fill and unvented attic applications

*R means resistance to heat flow. The higher the R value, the greater the insulating power. Ask your seller for the fact sheet on R-value.

Learn more about spray foam R-values here.

High-Density SPF Advantages

Builders often turn to high-density spray foam when high insulation values and strength are needed. As its name implies, this foam has a denser structure than either of the other types of spray foam. This spray foam is often an excellent choice for roofing or other exterior insulation because of its seamless, monolithic nature. High-density spray foam can also help reduce energy costs significantly over a roof’s lifetime due to its thermal resistance properties. It also offers increased protection against air and water infiltration and strengthens the structure to which it is applied. The bond that spray foam forms to the roof can increase a building’s resistance to wind uplift, which can help reduce damage experienced during periods of high wind.

Additional information on using SPF in roofing applications.

Medium-Density SPF Advantages

Medium-density foam is applied as low- or high-pressure two-component spray foam. Medium-density foam offers specific benefits depending on the climate and the type of building in which it is used. Like low-density foam, medium-density SPF is often used for continuous insulation, interior wall cavity fill, and unvented attic applications. However, medium-density is a closed-cell spray foam; it is often used where there is need for the greatest R-value insulation per inch possible. Medium-density foam acts as an air, vapor, and water barrier, and can even help reduce noise.

Medium-density foam can also provide a high tensile and bond strength. It can provide low vapor permanence and is often not affected by moisture such as wind-driven rains.

Low-Density SPF Advantages

Also known as open-cell-foam, low-density spray foam is spray applied to provide a continuous insulation and an air-sealing barrier. Low-density SPF is also called ½ pound foam, as it weighs almost 0.5 lbs. per cubic foot. The foam’s open-cell structure gives some flexibility to the hardened foam.

Low-density foam is applied as low or high-pressure, two-component polyurethane spray foam. Low-density spray foam can be applied on walls, in unvented attics, to ducts and ceilings, and in vented attics and crawl spaces. It is known as an air barrier, but permeable to vapor and moisture. It is often used to fill cavities in walls during construction.

Due to its relatively large cell structure, low-density foam stays somewhat soft and flexible after curing.. Low-density spray foam provides heat insulation and seals airflow through cracks, joints and seams by filling the cavities. In addition, this foam can help absorb sound thanks to its softer texture and open-cell structure.